Introduzione del prodotto del pannello in lana di roccia

Migliora il comfort e la privacy degli occupanti con i nostri pannelli acustici in lana di roccia di alta qualità. Progettati per applicazioni interne, questi pannelli ad alta densità assorbono efficacemente le onde sonore, riducendo la trasmissione del rumore attraverso pareti divisorie, soffitti e pavimenti. Forniscono contemporaneamente un eccellente isolamento termico, creando un ambiente interno più confortevole ed efficiente dal punto di vista energetico.

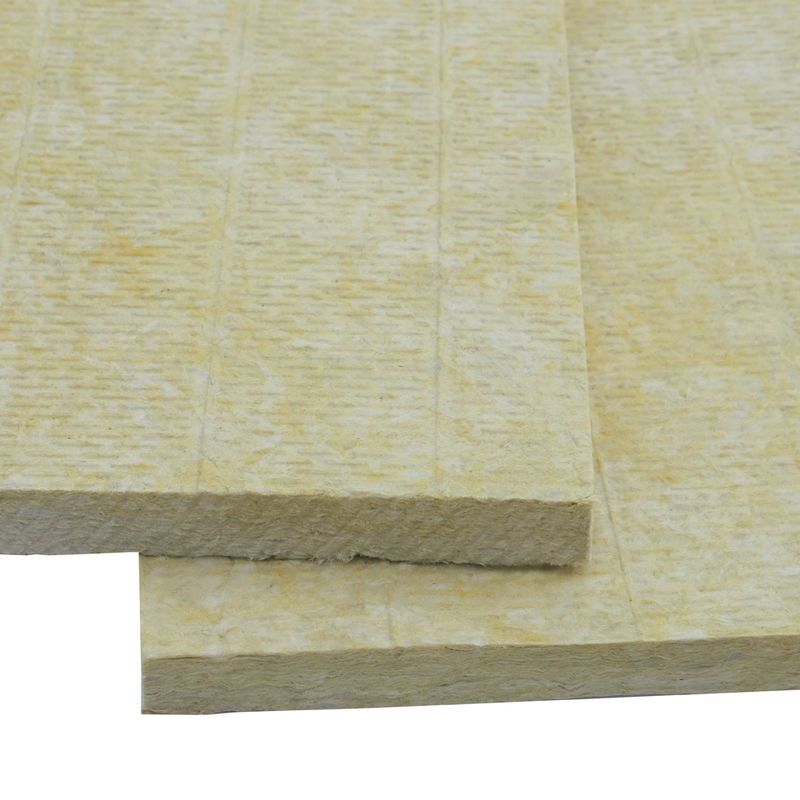

Immagine del prodotto del pannello in lana di roccia

Parametri del prodotto del pannello in lana di roccia

|

Proprietà

|

Pannello

|

Standard

|

|

Tolleranza della densità

|

±10%

|

GB/T 19686-2005

|

|

Resistenza al fuoco

|

Non combustibile

|

GB/T 5464-1999

|

|

Reazione al fuoco Classe A1

|

GB/T 8624-2006

|

|

Conducibilità termica

(W/mK, a 70±5℃)

|

≤0.044

|

GB/T 10295

|

|

Diametro della fibra

|

7(+/-1)um

|

GB/T 5480. 4

|

|

Contenuto di scorie

(dimensione scorie>0.25mm)

|

≤12%

|

|

|

Contenuto di umidità

|

≤0.5%

|

|

|

Contenuto di materia organica

|

≤4%

|

|

|

Punto di fusione

|

>1000℃

|

|

Dimensioni del prodotto del pannello in lana di roccia

|

Prodotto

|

Pannello

|

|

Densità (kg/m3)

|

40-200

|

|

Dimensioni: L x P (mm)

|

600X1200

|

|

Spessore (mm)

|

30-100

|

Caratteristiche del prodotto del pannello in lana di roccia

-

Assorbimento acustico efficace: Riduce la trasmissione del rumore aereo per una maggiore privacy e comfort.

-

Isolamento termico: Riduce i costi energetici minimizzando il trasferimento di calore attraverso le strutture interne.

-

Sicurezza non combustibile: Fornisce una classificazione antincendio di Classe A1, aggiungendo un livello di sicurezza agli spazi interni.

-

Leggero e facile da maneggiare: Facilita un'installazione rapida e semplice tra montanti e travetti.

-

Durevole e stabile: Non si affloscia né si assesta nel tempo, mantenendo le prestazioni acustiche.

Applicazione del prodotto del pannello in lana di roccia

-

Isolamento acustico in pareti divisorie interne e uffici modulari

-

Isolamento acustico in controsoffitti e pavimenti sopraelevati

-

Home theater, studi di registrazione e altri ambienti sensibili al rumore

Imballaggio del prodotto del pannello in lana di roccia

1. sacchetto di plastica

2. Busta termoretraibile in PE

FAQ:

Q1: Come garantire la qualità dei prodotti?

A1: Il nostro team di controllo qualità esperto ispezionerà la qualità del prodotto in ogni fase del processo

Q2: Come imballare le merci esportate?

A2: Sacchetto di plastica (Imballaggio standard per l'esportazione).

Q3: Qual è il tempo di consegna per un ordine di un container 40HC?

A3: Solitamente 15-20 giorni lavorativi dopo aver effettuato l'ordine

Q4: Qual è il tuo vantaggio sul pannello in lana di roccia?

A4: Un prodotto speciale con specifiche speciali può essere realizzato su ordinazione.

Q5: Per quanto riguarda il servizio post-vendita, come risolvere i problemi riscontrati dai tuoi clienti all'estero in tempo?

A5: La garanzia dei nostri prodotti è di un anno. Se i nostri prodotti o l'imballaggio presentano problemi di qualità, sostituiremo o compenseremo di conseguenza.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!